In-Mold Decorations: Revolutionizing Manufacturing Specifications

In-Mold Decorations: Revolutionizing Manufacturing Specifications

Blog Article

Grasping In-Mold Decorations: Strategies, Patterns, and Best Practices for Ideal Results

In the realm of manufacturing, the art of in-mold decorations stands as a critical element of item layout and manufacturing. In-Mold Decorations. By diving right into the strategies, trends, and best practices that underpin successful in-mold decoration processes, companies can unlock a realm of possibilities that not only elevate the aesthetic allure of their products but additionally streamline manufacturing performance and bolster customer involvement.

Product Choice

Material option is an important aspect of mastering in-mold decorations, as it straight affects the high quality and resilience of the last product. When picking materials for in-mold decors, it is vital to consider aspects such as compatibility with the molding process, the preferred visual result, and the ecological conditions the item will certainly face.

In addition, the selected product should possess excellent adhesion residential or commercial properties to make certain that the decoration adheres strongly to the substrate during the molding procedure. Attachment between the decoration and the material is vital for preventing delamination and making sure durable visual charm. Furthermore, products with high heat resistance are chosen for in-mold designs, specifically for items that will be exposed to elevated temperature levels during their lifecycle. By thoroughly choosing the ideal product for in-mold decorations, producers can improve the general top quality and durability of their products, meeting the expectations of both clients and end-users.

Design Innovation

An essential factor in advancing the area of in-mold decors is the constant exploration and implementation of design technology strategies. Style development plays an important role in enhancing the visual charm, functionality, and total high quality of items made utilizing in-mold design processes. By integrating cutting-edge style aspects, producers can differentiate their items out there, attract customers, and stay ahead of competitors.

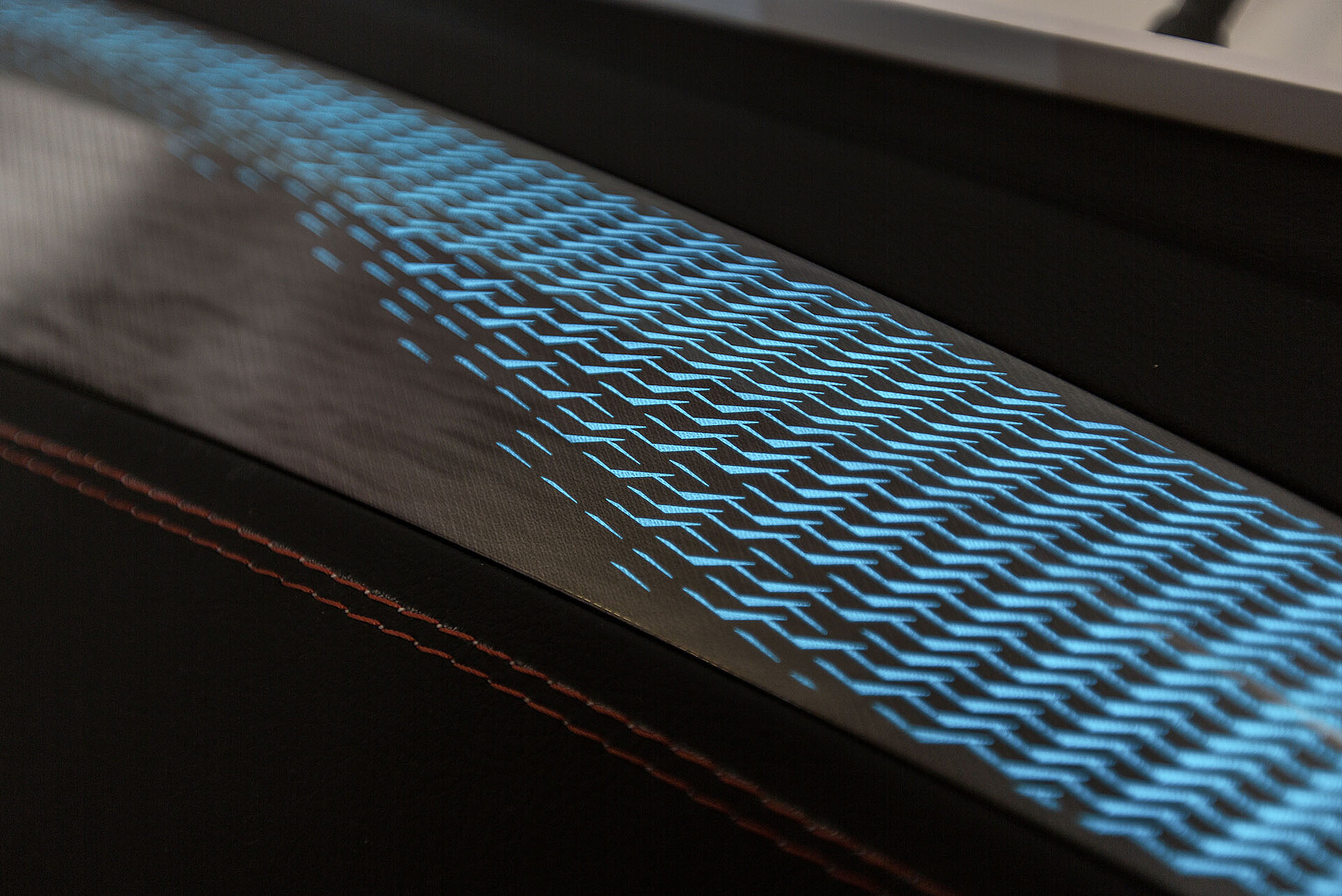

One of the vital elements of design technology in in-mold designs is the integration of detailed patterns, structures, and graphics that were previously testing to achieve with typical decoration methods. Advanced technologies such as 3D printing and electronic design devices enable developers to create facility and comprehensive layouts that can be effortlessly moved onto molded components. Furthermore, making use of dynamic shades, metallic coatings, and unique results like gloss or matte structures can further raise the aesthetic appeal of in-mold embellished products.

In addition, design advancement extends beyond appearances to encompass practical improvements such as ergonomic shapes, integrated attributes, and customizable aspects that provide to specific individual demands. By embracing design advancement, manufacturers can unlock new opportunities for personalization, imagination, and item distinction in the competitive landscape of in-mold decorations.

Production Effectiveness

Reliable manufacturing processes are important for translating the cutting-edge layouts established in the field of in-mold decors right into high-quality ended up items that meet market needs and customer expectations. In the world of in-mold designs, production performance includes various key facets that contribute to the total success of the manufacturing process.

In addition, executing automation and robotics in the production line can dramatically enhance efficiency by enhancing repeated jobs and decreasing the margin of mistake. Automation not only accelerates the manufacturing process however also boosts accuracy and repeatability, resulting in an extra uniform and high-quality end item. Furthermore, embracing lean manufacturing principles, such as just-in-time supply management and waste decrease strategies, can additionally boost manufacturing efficiency by decreasing downtime and enhancing source use. Generally, an all natural method to manufacturing performance is paramount in maximizing the capacity of in-mold design strategies and attaining optimal lead to the open market landscape.

Quality Control Steps

What are the essential techniques for guaranteeing strict quality assurance steps in the realm of in-mold decors? Quality assurance actions are extremely important in in-mold design processes to guarantee the production of premium and perfect finished items. One critical approach is the application of rigorous inspection methods at every phase of the production procedure. This includes conducting thorough aesthetic assessments, dimensional checks, and color uniformity evaluations to identify any kind of incongruities or flaws at an early stage.

Making use of sophisticated modern technologies such as automatic examination systems can likewise boost the quality control procedure by providing trustworthy and exact data for evaluation. These systems can detect flaws that might be missed out on by manual assessments, therefore improving general item quality and consistency.

Routine training and growth programs for employees associated with the in-mold decor procedure can also add to preserving premium criteria. By enlightening staff on finest methods, top quality assumptions, and the importance of attention i was reading this to detail, business can cultivate a society of top quality awareness throughout the organization.

Consumer Appeal

To improve the marketability of in-mold design items, recognizing and providing to consumer preferences play a vital role in determining their appeal and success. Consumer appeal in in-mold designs is influenced by various elements, including design aesthetic appeals, shade options, toughness, and total capability. Customers are progressively seeking personalized and distinct products that mirror their originality and design. Using customization alternatives such as tailored styles, shade variants, and textural components can substantially enhance the appeal of in-mold decor products.

Final Thought

In-mold decorations supply a flexible and effective way to boost item visual appeals. By thoroughly choosing materials, welcoming ingenious styles, maximizing production procedures, implementing quality assurance measures, and prioritizing consumer allure, suppliers can achieve optimal results. It is essential for business to continually adjust and improve their methods to remain competitive try here out there. In-Mold Decorations. Grasping in-mold decors needs a holistic approach that considers all aspects of the production procedure to make sure success.

In the world of manufacturing, the art of in-mold decors stands as a pivotal aspect of product layout and production. Design technology plays a critical function in enhancing the visual appeal, capability, and general quality of items manufactured making use of in-mold design processes.One of the crucial aspects of layout development in in-mold decors is the combination of detailed patterns, structures, and graphics that were formerly challenging to attain with conventional decor techniques.Reliable production procedures are important for Look At This converting the innovative styles developed in the field of in-mold decorations right into top quality ended up products that satisfy market needs and consumer expectations. Supplying customization choices such as personalized styles, shade variants, and textural elements can substantially boost the appeal of in-mold design items.

Report this page